Summary

Objectives. The goals of this study were to investigate the phase transformation and microstructure of dental porcelain bodies densified via a moving laser beam and to develop an understanding of how the microstructure of the dental porcelain varies with the laser processing condition and the position relative to the center of the laser beam.

Methods. A moving laser beam was used to scan and densify a commercial dental porcelain powder bed. The porcelain powder compact was also sintered using a furnace at different temperatures. The phase transformation and microstructure of these dental porcelain bodies were compared and investigated using a host of analytical instruments including scanning electron microscopy, X-ray diffraction,thermogravimetric analysis, and quantitative image analysis.

Results. Based on the temperature dependence of the leucite content in the dental porcelain derived from the furnace-sintered samples, the temperature distribution in the dental porcelain body during laser densification was established. The microstructure of the laser-densified porcelain body was found to be dependent of the location relative to the center of the laser beam and the average laser densification temperature.Significance. The understanding of how the microstructure of dental porcelain bodies varies with the laser processing condition and the location with respect to the center of the laser beam was developed. Based on this understanding, the laser processing condition has been optimized to achieve the desired microstructure and densification of dental porcelain bodies simultaneously.

Q2004 Academy of Dental Materials. Published by Elsevier Ltd. All rights reserved.

KEYWORDS

Dental porcelain;Laser densification;Phase transformation;Microstructure;Solid freeform,fabrication

Introduction

The dominant procedure currently used for perma- nent fixed prosthodontics is porcelain-fused-to- metal (PFM) restoration [1–5] . There are several steps involved in PFM restoration, including casting of a dental alloy base from a wax pattern of the patient’s teeth and building multiple layers of dental porcelains on the cast alloy base by several furnace firing processes. As such, PFM restoration is a time consuming and labor intensive work with labor costs accounting for about 90% of the final cost to the patient [5] . In order to reduce costs and provide faster and better service to dental patients, a new dental restoration method multi-material laser densification (MMLD), based on the principle of solid freeform fabrication (SFF), is being devel- oped [6–9] .

SFF is an automated manufacturing process that builds three-dimensional complex-shaped struc- tures layer-by-layer directly from CAD data source. More than 24 SFF techniques have been developed by research organizations and commercial com- panies in the recent past [10–12] , most of which scan an energy-delivery beam, e.g. a light, laser or electron beam in a computer-controlled pattern to densify a liquid or solid powder layer-by-layer in order to fabricate physical object directly from a computer model. In the MMLD process, both dental alloy and porcelain powders are delivered line-by- line or layer-by-layer, and subsequently densified by a laser beam, thereby the name of MMLD. Through this automated process, an artificial tooth is expected to be fabricated from a computer model without part-specific tooling and human intervention in an hour or two, and therefore MMLD offers the potential to substantially reduce the labor cost and increase the dental restoration rate.

In the MMLD process, it is expected that there exists a temperature gradient within the area irradiated by a laser beam because of the Gaussian distribution of the output power intensity of the laser beam. Thus, the temperature at the center of a laser-scanned path can be much higher than the average temperature of the sampling area, which is read by an emissivity-measuring infrared pyrometer that provides the temperature reading based on integration of the thermal radiation emitted by the sampling area. Temperature gradients are also present in the entire laser-densified body as densification is achieved by a moving laser source. Because of these temperature gradients, the phase transformation and microstructure of a laser- densified dental porcelain body may vary from location to location. Furthermore, the microstruc- ture and phases obtained may not be the desired ones because of the non-uniform temperature distribution. These issues are especially important for dental porcelain powders currently used in dental laboratories if they are utilized for the MMLD process. Most of the dental porcelain powders used today consist of two phases: the feldspar glass matrix and crystalline leucite par- ticles (K 2 O $ Al 2 O 3 $ 4SiO 2 ) [1–5] . The feldspar glass, which has a coefficient of thermal expansion (CTE) of 7–8 ! 10 K 6 / 8 C, relies on the presence of leucite particles, a high CTE phase (20–25 ! 10 K 6 / 8 C), to raise its CTE to match the CTE of the dental alloy (typically 13–16 ! 10 K 6 / 8 C). Without the match in CTE between the dental porcelain and alloy, cracking in porcelain develops during the PFM fabrication process [2,13] . Similarly, cracking is expected to occur in the MMLD process if the CTE mismatch is not minimized or eliminated. There- fore, there is a critical need to investigate the phase transformation and microstructure of dental porcelain bodies densified via a moving laser beam. To meet this critical need, the aims of this study are to: (i) investigate the phase transformation and microstructure of dental porcelain bodies densified via a moving laser beam; (ii) develop an under- standing of how the microstructure of the dental porcelain varies with the laser processing condition and the location with respect to the center of the laser beam; and (iii) based on the understanding developed, optimize the laser processing condition to achieve the desired microstructure and densifi- cation of dental porcelain bodies simultaneously.

Materials and methods The dental porcelain powder Ceramco q II Silver Body (batch number 99081250) was provided by Dentsply Ceramco, Burlington, NJ. The chemical composition of the porcelain is confidential; how- ever, it is within 5% of the nominal composition of the Component No. 1 in Weinstein patent, which is SiO 2 —63.40%, Al 2 O 3 —16.70%, K 2 O—14.19%, Na 2 O— 3.41%, CaO—1.50%, and MgO—0.80% (wt%) [13] . The as-received porcelain powder had angular shapes and their equivalent particle sizes ranged from 5 to 50 m m. Furthermore, the powder contained two phases, the feldspar glass matrix and the crystalline leucite particles. Laser densification of the dental porcelain powder was conducted using an integrated SFF system, a schematic of which is shown in Fig. 1 .In the laser densification process a continuous wave laser beam from a 50 W CO 2 laser was steered into a process chamber with a controlled atmosphere by a series of motion-controlled mirrors. The scanning and sintering of the desired area of a powder bed within the process chamber was achieved via an x – y table controlled by a computer. The entire densi- fication process was closed-loop-temperature controlled using a pyrometer by comparing the pyrometer reading with a user-defined target sur- face temperature (termed as the target tempera- ture hereafter). The powder bed was a dried paste, which was prepared by delivering dental powder paste onto a steel substrate and the paste became dried when the substrate was heated. The steel substrate could also pre-heat the powder bed to 400 8 C during the laser densification process to reduce or eliminate thermal shock-induced cracks in porcelain bodies. The typical laser experimental conditions included the laser beam diameter of 1 mm, the scanning rate 0.24 mm/s, the chamber pressure 700 Torr, and the user-defined target temperature 800–1100 8 C with an equivalent laser output power of about 3–20 W.

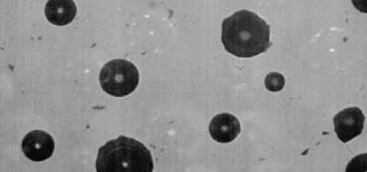

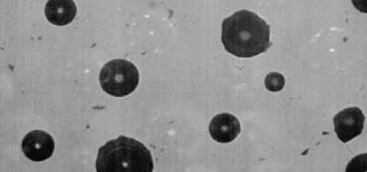

In order to establish the relationship between the microstructure of laser-densified and furnace- sintered dental porcelains, a thermogravimetric analyzer (TGA) system was utilized to sinter the dental porcelain powder. Eight sintering tempera- tures 750, 800, 900, 1100, 1200, 1300, 1400, and 1500 8 C were investigated with a heating rate of 10 8 C/min, a cooling rate of 50 8 C/min, and a holding time of 5 min. The as-received dental porcelain powder, the laser-densified and TGA furnace-sintered samples were mounted using an epoxy resin, followed by grinding and polishing down to 1 m m diamond suspension. The laser-processed samples were mounted and then cut in such an orientation to reveal the cross-section perpendicular to the laser scanning direction. To determine the existence of the leucite phase, the polished samples were etched using 1% hydrofluoric acid for 20 s. An environmental scanning electron microscope (PHI- LIPS ESEM 2020) was used to examine the micro- structure of all the samples at as-polished and etched conditions after being carbon sputter- coated. The ESEM images with the sam magnification were analyzed using a Context Vision w multi-mode image analyzer to determine the area/volume fraction of voids in samples not etched, or the leucite phase in etched samples. For furnace-sintered samples at least 10 different ESEM microphotos were taken to perform the quantitat- ive image analysis and the mean value was reported. For laser-densified dental bodies, 12 different locations were selected, and at least five ESEM micrographs were taken around each location in order to perform the quantitative image analysis. Through this procedure, the volume fraction of the leucite phase in laser-densified samples as a function of the location with respect to the center of the scanning laser beam was determined. To evaluate the phase transformation as a function of the TGA holding temperature and relate the microstructural evolution to the phase trans- formation, the TGA furnace-sintered dental porce- lain chunks were pulverized using a mortar and pestle, and the powders so obtained were analyzed using X-ray diffraction (XRD) to investigate the existence of crystalline phases..